Electronic Controllers

From design and prototyping to volume production, AFS can create a custom-engineered engine controller for your application – quickly and efficiently.

Today’s engines rely on the engine control module (ECM) and its software to meet increasingly higher customer expectations. Balancing power, durability, fuel efficiency, driveability, exhaust emissions and cost requires a carefully-optimized controller package. AFS understands the varying expectations and operating conditions in different markets – we’ve produced a wide range of products, from inexpensive controllers optimized for developing countries, to those requiring the latest on-board diagnostic compliance, ultra-low emissions and integrated powertrain and peripheral control.

Engine controllers are computers and they follow the same dynamic cost vs. performance trends as home PC’s and laptops. To stay current in the industry, our engineers watch for new chips and technologies and quickly take advantage of these new developments. For customers, this means a continually improving opportunity to balance cost and processing power, and potentially to integrate previously separate functions.

During

the manufacturing process, AFS carefully controls component sourcing and

component quality control in-house. Depending on order size, we work

with one of several carefully qualified contract manufacturing partners

for the circuit board population process. This allows us to choose

the most appropriate vendor for the size and technical details of the circuit

board, specify new technology components without consideration of in-house

equipment limitations, and fill large orders quickly without a manufacturing

bottleneck. AFS specialists perform thorough end-of-line quality assurance

using AFS-designed automated testing equipment.

Features we’ve provided for our customers include:

- 8, 16 or 32-bit processors, 2 to 40 MHz

- 12 and/or 24 Volt – some controllers offer auto-voltage sensing

- tri-fuel, bi-fuel or monofuel

- integrated or external ignition coil drivers

- CAN bus (J1939) communication – multiple if required

- K-line (ISO 14230 or KWP 2000) communication

- ATA (J 1587) communication

- stoichiometric (λ=1) or lean-burn (λ>1) combustion

- in-cab or weatherproof enclosures for underhood or on-engine mounting

- robust overvoltage and reverse polarity protection

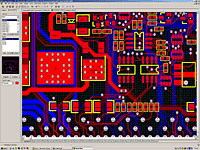

- multi-layer circuit boards for enhanced EMI, RFI resistance

- configurable analog and digital I/O

- configurable proprietary injector driver circuitry for calibratable peak & hold or saturated injectors – provides compatibility with most injectors

- single or dual knock sensing

- electronic throttle (drive-by-wire) control with enhanced engine speed governing

- torque-speed control strategies

- vehicle speed limiting

- fully configurable diagnostic trouble code management

- custom or industry-standard timing pickup disk compatibility

- fleet analysis tools for detecting abnormal engine operation or vehicle abuse

- automated end-of-line burn-in and test procedures

- electronic serializing

- vehicle-specific systems configuration

- 23 to 121 pin connectors and enclosures

Reliability in automotive controllers doesn’t happen easily. It comes from field experience, knowledge of real-life use and abuse patterns, listening to customer feedback, and careful design and quality control. AFS has designed more than 40 controllers since 1995, and with tens of thousands of engine controllers sold, we have developed an enviable reputation for durability in the most demanding applications.

Let AFS provide the competitive electronics you need for your engine control projects. We’re happy to put your company’s name on the label and in the calibration software, and we’ll work with you on every step of the process.